LEESBURG, VA—The high–level objectives of the DADSS Program are two–fold. First, successfully develop and commercialize one or more vehicle–integratable technologies to passively measure a driver’s blood alcohol concentration (“BAC”) with the high precision and accuracy needed. Second, facilitate the deployment of commercialized DADSS technologies as widely as possible as rapidly as possible.

This post answers the question that comes up with increasing frequency as the development status of the technology matures and approaches commercial deployment: “When can I expect to see cars and trucks in dealer showrooms with the DADSS technology installed?”

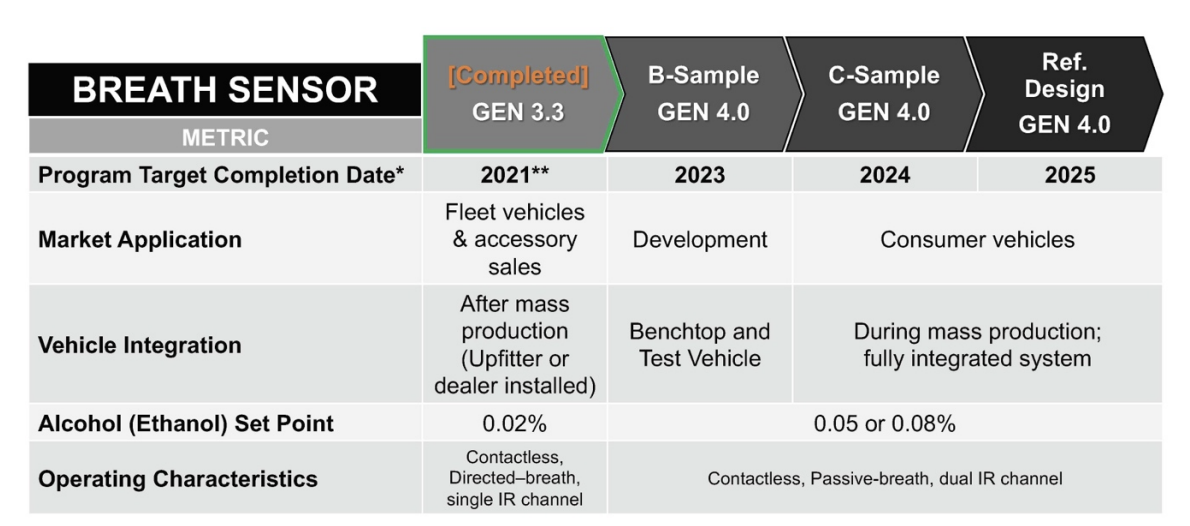

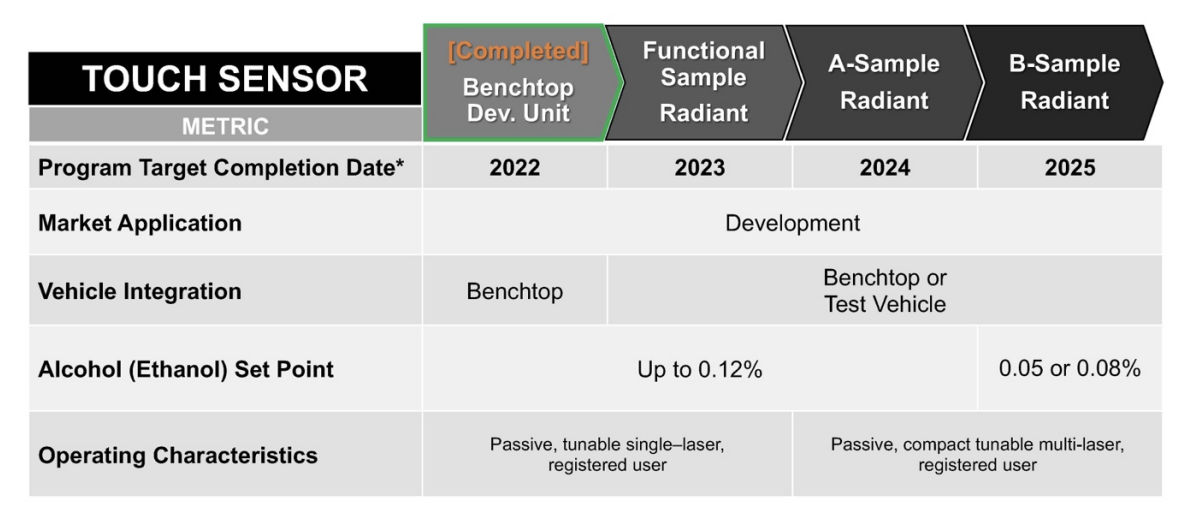

Figures 1 and 2 provide a high–level timeline for the development of the DADSS breath and touch sensors. The automotive industry works with so–called samples (A, B, C, D), providing components or systems under development as prototypes with increasing functionality and maturity. The different levels of samples used are briefly defined as follows:

- Functional Sample: Sample with one or more functions or concepts; test of concepts

- A Sample: Functional prototypes, usually with limited functionality or driveability and low degree of maturity

- B Sample: Functional, basic prototypes with full functionality or driveability and a high degree of maturity; may be created from pilot tools

- C Sample: Fully functional sample manufactured with series production tools

- D Sample: Same as C Sample, provided by suppliers for the purpose of the design sample release

The Program’s target completion date (*) is the date by which the Program intends to transfer a completed DADSS design to product integrators. Product integrators include auto suppliers, auto manufacturers and others who make and install, or contract to have made, integrated and aftermarket products.

Automakers will need additional time to integrate a DADSS sensor into a new car or truck model and conduct the necessary verification and validation (“acceptance”) testing at the vehicle level to confirm that the DADSS sensor or system performs reliably as intended over the life of the vehicle. This work is likely to take at least 18 to 24 months or longer. See Figure 3.

The DADSS Program has adopted the electronics industry’s reference design concept for licensing and transferring commercialized DADSS products to product integrators. A DADSS Reference Design includes schematics, specifications, minimum hardware requirements, and other documentation relating to the hardware design of the DADSS product being licensed. DADSS Reference Designs will have completed acceptance testing at the component or system level.

ACTS has established an open licensing process for all DADSS Reference Designs commercialized by the Program. Open licensing means the technology will be made available, on the same terms, to any product integrator interested in installing the technology into their products or vehicles.

In December 2021, the Program released its first DADSS Reference Design (**). This Design uses a DADSS breath sensor and is intended for use in commercial vehicles used by fleets adopting a zero–tolerance policy for drivers. This first–generation system does not operate passively; it requires only a limited breath sample—like blowing out a candle. Automotive aftermarket and non–automotive products, such as access control for entry into safety–sensitive areas, that use this sensor are anticipated to be introduced late in 2023. See https://actsautosafety.org/announcementpage/.